Let’s meet @ Wire Dusseldorf 2024!

We are waiting for you with great pleasure at Wire in Dusseldorf from 15th to 19th of April 2024. You will find us in hall 11 stand B52, where you can meet our staff that will show all the news and special technical details about our 100% Made in Italy products: crossheads, extruders, extrusion lines […]

The new Antonio Gumina’s book is now available

We are pleased to annunce that the new book of our CEO Antonio Gumina, Extrusion process & problem solving for cables production, is now available. Here below a brief explanation of main topics. What happens, why it happens, how to solve and calculate. This book has been written with the merely scope to help operators, […]

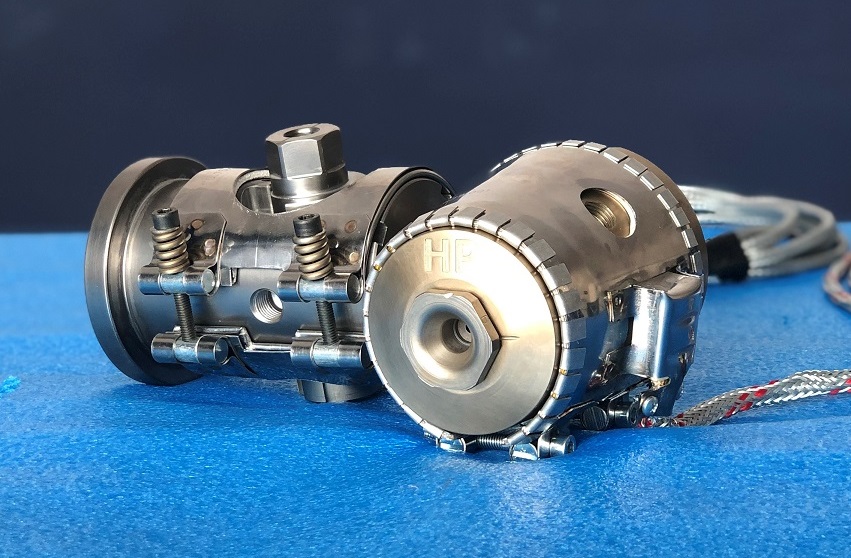

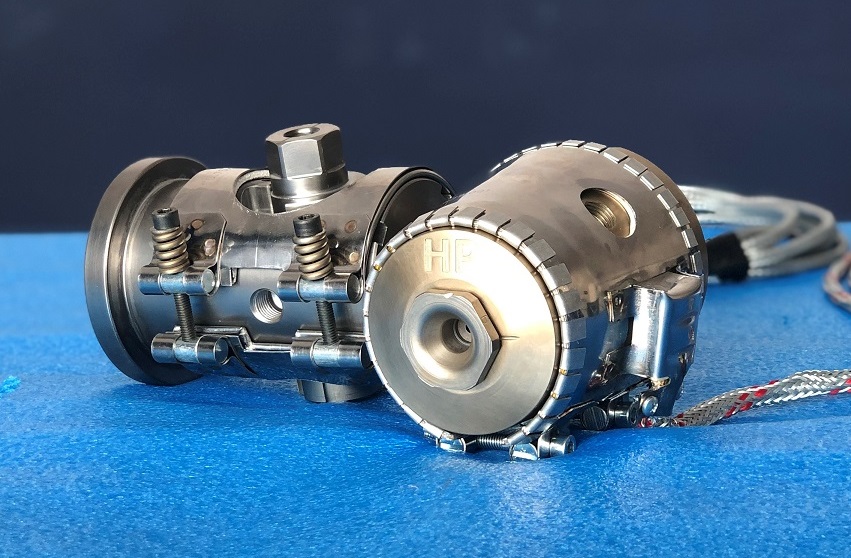

[ENG] HP-CN, the unique conical head to process all compounds

HP Extrusion has developed and already sold HP-CN, the unique conical cross-head on the market processing all compounds, as well as high viscosity compounds, with perfect heat distribution, higher concentricity, lower pressure and low thermal consumption. The head HP-CN, due to its design, proper melt flow distributor, tool chamber and new treatment HPT5X can easily […]

[ITA] HP-CN, l’unica testa conica nel mercato per tutti i compound

HP ha sviluppato e produce HP-CN, l’unica testa conica nel mercato che permette di processare tutti i compound con una perfetta distribuzione del calore in tutte le sezioni di flusso, elevata concentricità, pressioni di esercizio ridotte e ridotto assorbimento. La testa HP-CN grazie al suo design e al dettagliato dimensionamento del convogliatore, sezioni di flusso […]

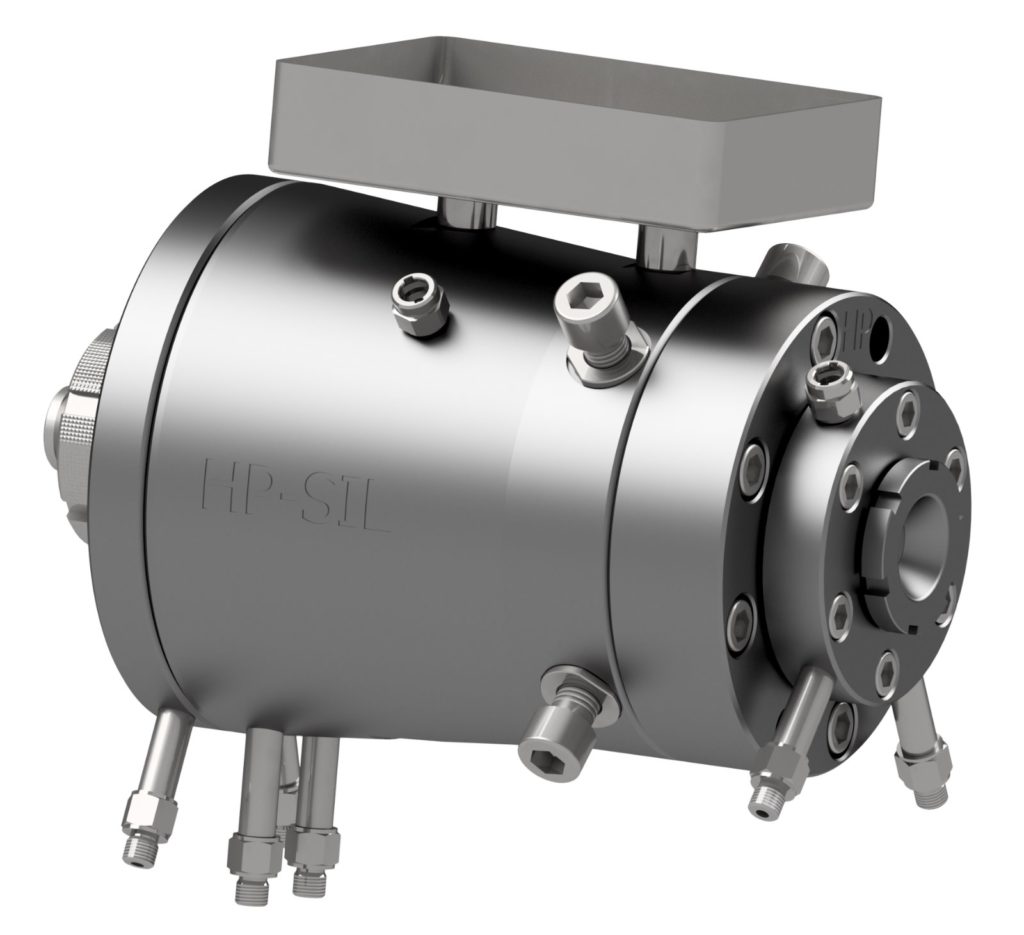

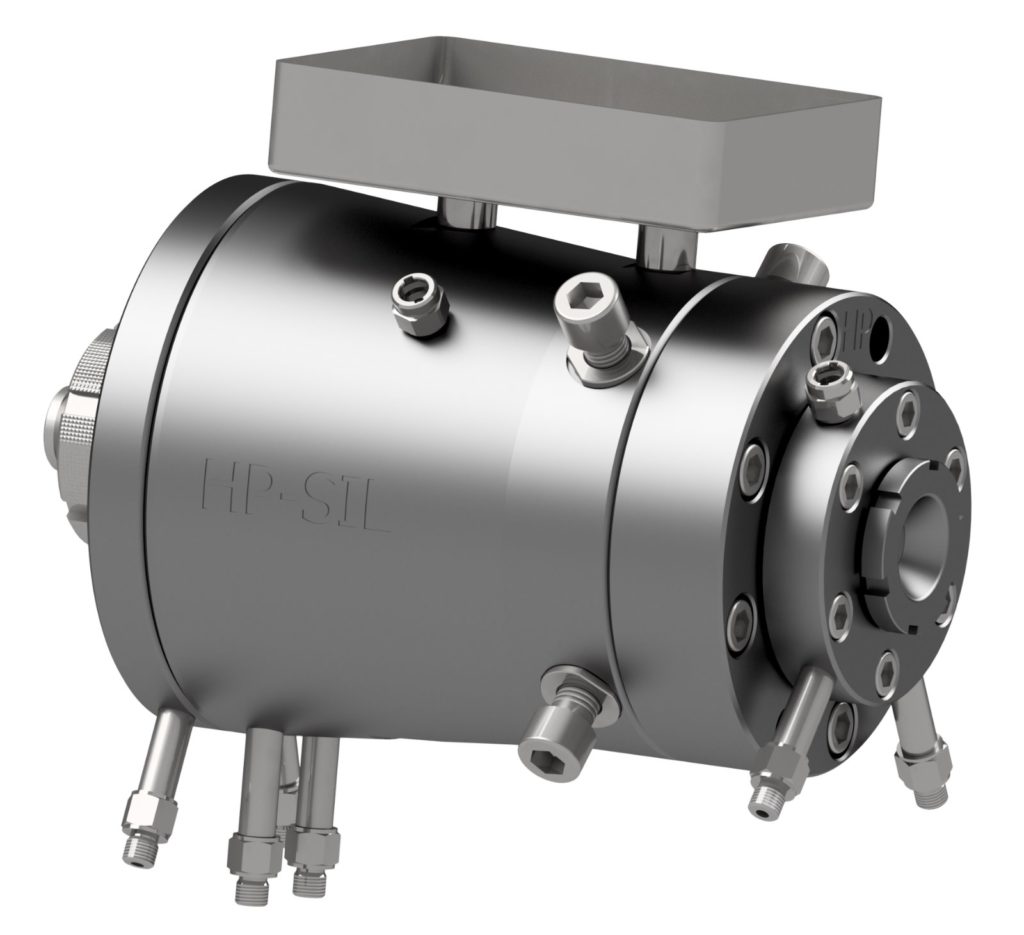

[ENG] HP-Sil, the HP new generation head for silicone and rubber

HP Extrusion has developed the Co-extrusion compact head for silicone, the HP-Sil New Generation Head. The HP-Sil is made with latest generation materials and treatments. Furthermore, the performing and optimal flow distributor guarantees the correct distribution of the material around the cable, eliminating risks of material stagnation, lower mechanical friction and lower working pressure. For […]

[ITA] HP-Sil, la nuova generazione di teste per silicone e gomma

HP Extrusion ha progettato una testa di estrusione per silicone a centratura fissa e manuale, in coestrusione con possibilità di skin, HP-Sil New Generation Head. La HP-Sil è realizzata con materiali e trattamenti di ultima generazione tali da garantire una elevata scorrevolezza del compound al suo interno evitando ristagni ed innalzamenti di temperatura e pressione […]

[ENG] Latest news: how to receive our technical newsletter

Starting from the 29th of July, our technical newsletter will be sent directly via e-mail, in a pdf format, due to privacy and company’s know-how protection concerns. The newsletter will be no longer available in our website. If you are interested on receiving the newsletter, you can e-mail at info@hpextrusion.com: our team will give you […]

[ITA] Come ricevere la nostra newsletter tecnica

A partire dal 29 luglio le nostre newsletter saranno inviate direttamente via e-mail, in formato pdf, e non è più prevista la pubblicazione su questo sito, per ragioni di riservatezza e di tutela del know-how aziendale. Chiunque fosse interessato a riceverle può scrivere all’indirizzo info@hpextrusion.com e saranno comunicate le istruzioni per la ricezione. Grazie per […]

[ENG] Silicone process and cross head for silicone

For silicone production it is important the design of: Extrusion cross head Extruder Vulcanization process and mode. The critical parameters for the extrusion of silicone or silicon rubbers are: Moisture temperature into the extruder and cross head Working back pressure that can generate compound over-heating due to the viscous friction. Material stagnation into the […]

[ITA] Silicone e teste di estrusione per silicone

Per il processo di produzione di un cavo in silicone, di rilevante importanza è la corretta progettazione di: Testa di Estrusione Estrusore Circuito di raffreddamento di testa e vite Sistema di reticolazione ed eventuale raffreddamento del cavo. I parametri critici per l’estrusione del silicone o gomme siliconiche sono: Temperatura della mescola in estrusore e testa […]