[ENG] Extrusion and cross heads

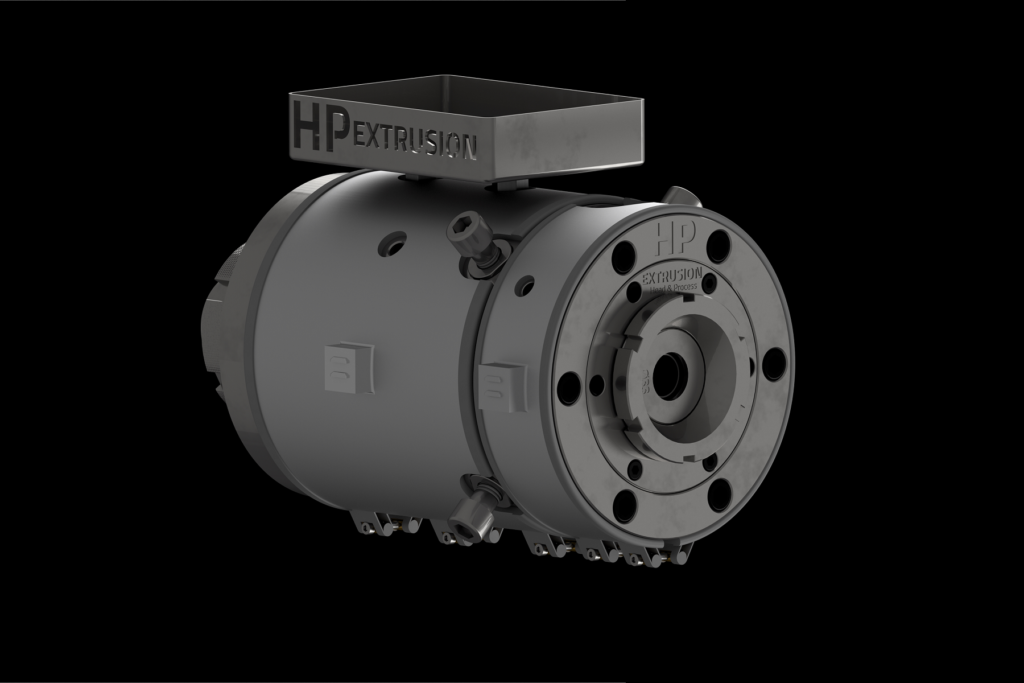

The extruder and cross head are the most important components that constitute the extrusion line. Regarding the extruder, very important is the design of the screw and barrel and thermoregulation system. Let us remember that the screw profile, its compression rate and screw rpm acts on the visco-elasticity of the compound processed which enters into […]

[ITA] Estrusione e teste di estrusione

Tra i componenti più importanti di una linea di estrusione, che incidono sulla produzione e qualità produttiva, abbiamo l’estrusore e la testa di estrusione. Per un estrusore di fondamentale importanza sono le caratteristiche del cilindro e della vite di estrusione, associato al suo sistema di termoregolazione. Ricordiamo che la vite in termini di profilo, rapporto […]

[ENG] Tips, dies and inserts

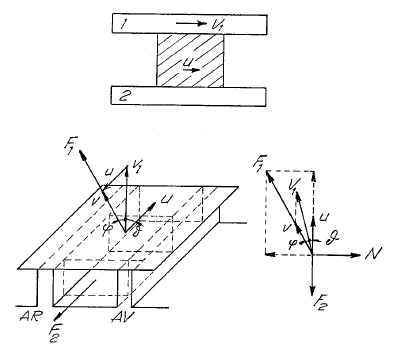

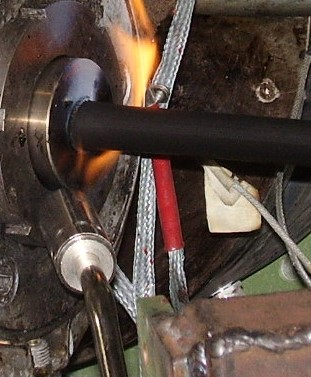

The choice of the tips and dies, in terms of their dimensions and geometric conformation and shape, is an important factor for the extrusion process. The tips and dies can be classified according to: construction characteristics and geometric/processing characteristics. CONSTRUCTION CHARACTERISTICS Concerning the construction characteristics, the tools can be differentiated by: fixing system, mainly for […]

[ITA] Guidafili, filiere e inserti

La scelta degli stampi è di fattore di rilevante importanza nel corretto processo di estrusione, sia in termini di calcolo delle dimensioni per il cavo/filo da produrre che in termini della conformazione geometrica e processuale. Gli stampi, sia guidafili che filiere, possono essere classificati in base a caratteristiche costruttive, geometriche e processuali CARATTERISTICHE COSTRUTTIVE […]

[ENG] Screws, skin rings and distributors

In the extrusion process an important role is played by extruder screw, flow distributor design, ring for skin and stripes design, tools chamber. They must be designed in according with the compound property and rheology to be processed, minimum and maximum extruder output and type of process. Most of the roles used for screw calculation […]

[ITA] Viti, anelli skin, convogliatori

Nel processo di estrusione svolgono un ruolo fondamentale il design di viti di estrusione, convogliatori di flusso, anelli di distribuzione per skin-riga. camera stampi. Essi devono essere progettati tenendo in considerazione il tipo di compound da processare, la portata minima e massima erogata dall’estrusore adoperato e tipo di processo. Molte regole e concetti generali usati […]

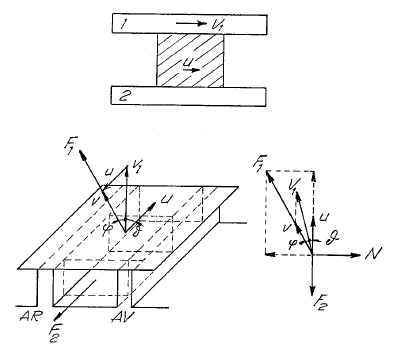

PEX-B: XLPE Monosil

The XLPE for cable insulation can follows different process: Monosil Sioplas Visico® In this section we will deal with XLPE Monosil. Cable insulation in XLPE by monosil process (liquid silane) allows to produce the cable in according with all needs and requirement or specification to be respected. This advantage is due to the possibility to […]

PEEK: Polyetheretherketone

PEEK is a Polyetheretherketone, and it belongs to the Superpolymers category. The PEEK is a thermoplastic aromatic polymer. It is semycrystalline polymer. The melting temperature is around 343 °C and for this reason it has been processed between 380 – 420 °C. The extruder temperature profile depends on the extruder size, screw profile, screw rpm, […]

Ready for our first extrusion tip?

In the next days we will launch our blog with tips, suggests and information about extrusion process.